OUR HISTORY

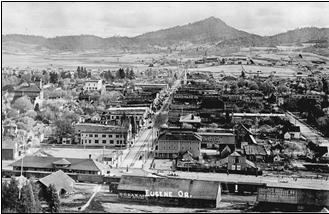

Commercial Dehydrator Systems, LLC (CDS), and it's sister company Miller Dehydrator Company (MDC) can trace their origin back to the sale of a Prune Orchard, and an old Natural Draft Prune Dryer located in Eugene, Oregon in the year 1911. Having purchased the orchard and dryer, Mr. L. N. Miller immediately began to up-grade the old equipment using his skills and experience from building organs, Mr. Miller applied that knowledge to the Dryer. He used electric powered fans to increase the air velocity through the Dryer, and dramatically improved the unit's production. He continued to experiment and improve the system. Due to his success, Mr. Miller was given the task of upgrading all 1000 Dryers of the Oregon Prune Exchange.

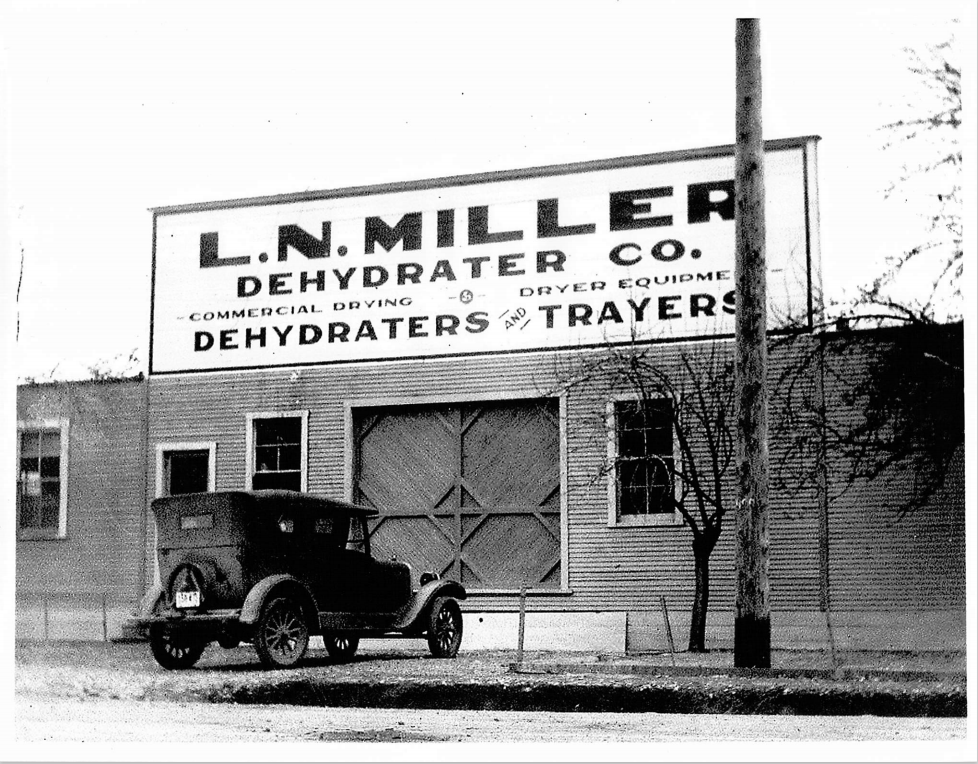

By 1918 Mr. Miller had refined his system to a point where he sought existing manufacturers to incorporate this new technology into their designs. They refused. The following year Mr. Miller designed a totally new Dryer, The Tunnel Dryer. 1920 saw the introduction of the new Dryer, and the formation of the L. N. Miller Dehydrator Company. Both were an immediate success.

In 1988, the Miller Dehydrator Company reorganized into Commercial Dehydrator Systems, Inc. as the manufacturing element, and the Miller Dehydrator Company name survives as the custom drying operation co-located with CDS in Eugene, Oregon.

Continuing with Mr. Miller's original intent, CDS is actively involved in the Oregon and California Prune Industries, as well as a wide range of other food and agricultural endeavors. CDS provides Tunnel Dryers, Traying Lines and ancillary support equipment, as well as Belt Dryers and Bin Dryers for Almonds, Hazelnuts, Pistachios Walnuts, and Bark. Overseas applications include Drying and Roasting Macadamia Nuts, drying Mushrooms, and Hot Forced Air Treatment Chambers for tropical fruit.

Designed for the family farm, the Miller Dryer proved to be very effective in a wide range of climates. Acceptance of this new technology grew and soon The Miller Dryer became the product of choice through out the country.

During World War II, the U.S. government evaluated the various systems then available, and chose the Miller Dryer to support the nation's Cannery Industry. A Miller Dehydrator was installed at every major cannery in the country, as a back up in case of enemy sabotage. After the war the Canneries sold or gave away many of the Dryers. To survive, Mr. Miller developed equipment to support the Dryers, including Traying lines and post dehydration handling and processing equipment.

In 1951, E. LeRoy Stone joins the Miller organization as an accountant, and draftsman. Mr. Miller and Mr. Stone actively pursue the dehydration business, primarily on the west coast, and concentrating on fruits, vegetables, and nuts. Mr. Miller died in 1958, and the heirs made Mr. Stone the General Manager. After a short period, Mr. Stone bought the company.

Under LeRoy Stone, the Miller Dehydrator Company branched out in to Bin Dryers for nuts and wood products, Belt Dryers and Roasters and rapidly accelerated research and development into a wide range of dehydration products. The Bulk Tank , which is used in virtually every Prune Dryer in the United States, first took form on the MDC drafting board.

In 1988, the Miller Dehydrator Company reorganized into

Commercial Dehydrator Systems, Inc. as the manufacturing element, and the Miller Dehydrator Company name survives as the custom drying operation co-located with CDS in Eugene, Oregon.

The year 2020 marks a new era for

Commercial Dehydrator Systems, LLC when Clay Fisher purchased the company from the Stone family. Using our over 100 years of experience in the business drying every imaginable product we can find a solution for any of your drying needs.