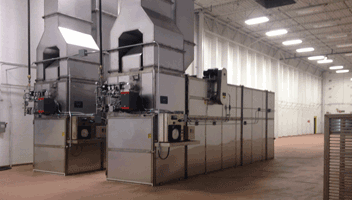

McKenzie Tunnel Dryer / Dehydrator

Our McKenzie Tunnel Dehydrator blurs the separation between cabinet and tunnel dryers. The McKenzie is unique due to its small footprint, yet utilizes mobile racks carrying trays, like our larger systems.

The McKenzie Dehydrator is expandable from standard 1,595 sq. ft. (148.18 sq m) to triple the capacity, with minimal additional investment. Versatile and effective the McKenzie Tunnel Dehydrator is an outstanding choice for rapidly growing businesses. Drying trays, product liners, and mobile racks sold separately.

McKenzie Features

Energy Efficient - Flexible - Expandable

Control Humidity & Reduce Drying Time Up to 50%

- Extra Large Drying Trays

Extra large 24" length by 38" width drying trays. Standard McKenzie capacity is 252 trays across 6 mobile tray racks.

- Powerful Variable Fan

The VFD (variable frequency drive) is designed for fan speed control. Allowing the operator full control over air speed within the unit.

- Thermostatic Temp

Every McKenzie comes standard with a thermostatic temperature controller capable of ambient temperatures up to 220°F (104°C).

- Automated Humidity Control

Each unit comes standard with an Automated Humidity Control System which helps reduce drying times.

- Gas Burner

McKenzie operates on your choice of gas type. We can customize your dryer for use with natural gas, propane gas or butane mix.

- Expandable For Growth

Expand your McKenzie Dehydrator with your business at a fraction of the cost.

Product Description

The McKenzie Tunnel Dehydrator is one of our most popular Dryer Systems. Capable of expanding to triple the capacity, the McKenzie Tunnel Dehydrator is one of the most powerful tray-and-cart tunnel dehydrators on the market today. For a rapidly growing business, the McKenzie Dehydrator is a perfect solution for food items like fruits, proteins, vegetables, herbs, and pet-treats to non-food materials in batch volume.

The standard non-expanded McKenzie offers 1,595 sq. ft. (148.18 sq m) of drying space utilizing 252 (24-in by 38-in) stainless steel drying trays across 6 mobile tray racks (42 trays each rack). Each unit comes equipped with VFD (variable frequency drive) which provides the operator full control over air speed within the unit and Automated Humidity Control, which significantly reduces drying time.

The McKenzie Tunnel Dehydrator can be expanded by three additional sections, without the purchase of a complete dryer. Each section adds approximately 1,063 square feet of drying space across 168 trays with 4 mobile racks.

Configuration Options:

Standard McKenzie - 1,595 square feet drying space. 252 trays & 6 mobile racks

McKenzie Extension 1 - 2,658 square feet drying space. 420 trays & 10 mobile racks

McKenzie Extension 2 - 3,722 square feet drying space. 588 trays & 14 mobile racks

Fully Extended McKenzie - 4,785 square feet drying space. 756 trays & 18 mobile racks

Note: Every dehydration system is unique and may require custom configuration for your business or product. Because of this, pricing listed above is the base price of the dryer. Intake, exhaust and ducting are not universal and require dimensions of your facility to quote. Drying trays, product liners, and mobile racks sold separately.

Tunnel drying systems are purchased through installment payments, with the final balance due upon completed installation. Contact a sales representative today.

Proudly Made in Eugene, Oregon USA.

Achieve Industrial Level Dehydration

Supporting Tools

Economy Moisture Balancer

Water Activity Meter

Perforated or Solid Drying Trays

Mesh or Solid Tray Liners

Mobile Tray Racks

Technical Specs

| Model # | McKenzie |

| Temperature Range | Ambient to 220°F (104°C) |

| Tray Size | 24" D x 38" W (inches) |

| Dimensions | 210” x 61” x 146” (standard) |

| Machine Weight | 15,900 Lbs (7,212 kg) |

| Fan Motor | High-Velocity 15 HP |

| Avg. Fan Load | 12 kW/hr (12,000 watts) |

| Avg. Heat Load | 520,000 BTUs |

| Max. Heat Load | 1,300,000 BTUs |

Estimated Running Costs

| Standard McKenzie | Result |

|---|---|

| Average Running Cost | $11.50 / Hour |

| $276 / Day (24 hours) | |

| $0.17 / Sq Ft / Day |

Note: All heating loads were computed based on a 40% consumption rate. This is an average figure (0.12 Kwh), and may not accurately represent all applications.